Ultrapure Water for Electrolysis

- Feed Water – Ultrapure Water Treatment (High Purity) for Electrolysis

- Recirculation Purification – Water Refinement for Electrolysis

Feed Water – Ultrapure Water Treatment Systems / Central DI-Water Systems

The purification of drinking water to ultrapure water for final PEM electrolysis is carried out in multiple process stages, tailored to the existing water quality, with detailed engineering and the use of combined process technologies:

- Pre-filtration (backwash filters, sand filters, ultrafiltration)

- Water softening systems / alternative antiscalant dosing

- CO₂ removal via membrane degassing

- Desalination >99% via reverse osmosis

- Full deionization via a second RO stage or electrodeionization (CEDI)

Recirculation Purification – Water Refinement for Electrolysis

A fundamental feature of our systems is recirculation purification to recycle contaminated process water. The recirculation purification is either directly integrated into the feed water treatment or added as a stand-alone unit to an existing process water treatment system. The process water, which operates at up to 50 bar and can reach temperatures up to 65°C, is economically degassed and desalinated using a method suitable for continuous operation. All our systems are provided in a modular design, allowing for custom integration into the overall electrolysis concept.

Recirculation purification that meets all requirements!

Process water recirculation purification for continuous desalination to <0.1 µS/cm

Particle filtration <1 µm

Hot water HD polisher

Plug & Play: Easy handling system for quick polisher replacement

Degassing system for removal of residual H₂ and O₂

Process water supply system with storage tank and pressure boosting units

Process water cooling unit (optional)

UV system for TOC reduction

Modular systems up to 2,000 l/min

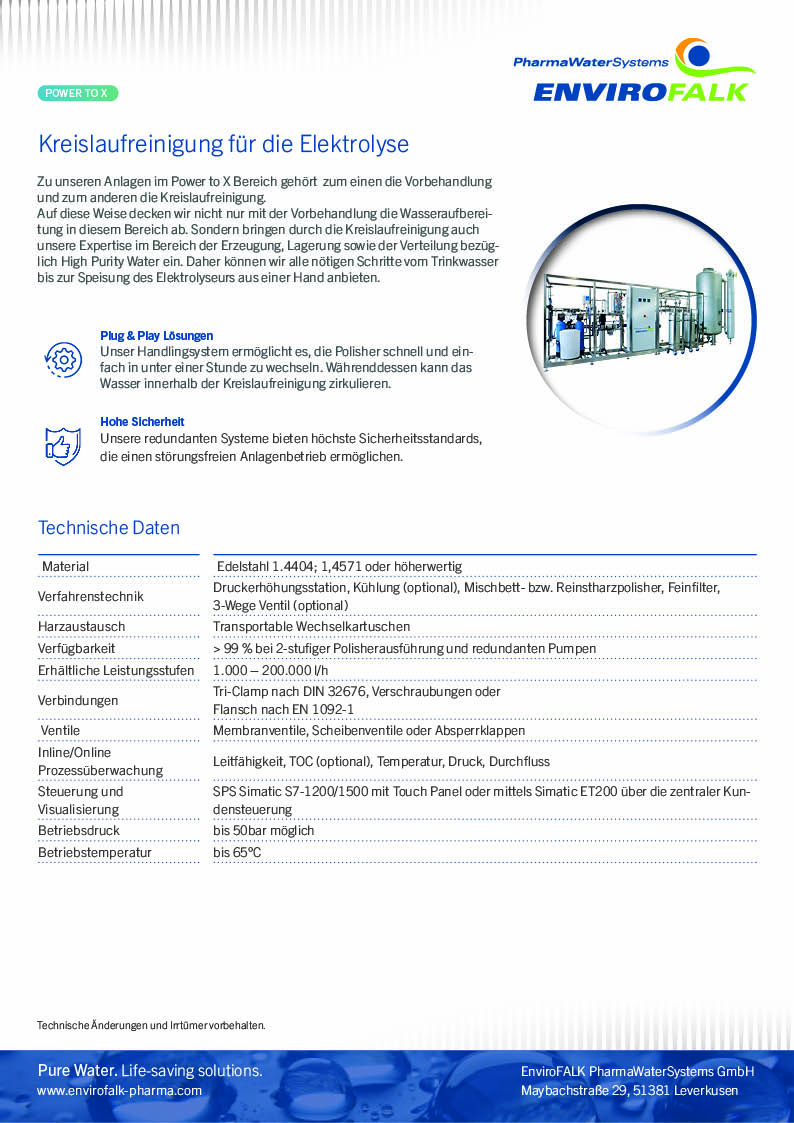

This is what your finished system could look like!

Service

We offer services ranging from the smallest spare part to full-scale plant maintenance. Contact us to learn more about our comprehensive support services!

Trade Fairs & Events

When it comes to solutions for your water treatment, experience genuine enthusiasm in a personal conversation at our trade fairs and events. Get to know us!

References

Many of our customers are leading companies in their industry that have trusted EnviroFALK water treatment systems for years. See for yourself!

Downloads

Customers & Solutions

Pure Media Systems for the New Production Facility of Allergopharma

EnviroFALK PharmaWaterSystems delivers everything. Receive a comprehensive production line that is fully aligned in terms of functionality and quality.When... mehr lesen

Trust That Pays Off - Gerresheimer Relies on EnviroFALK PharmaWaterSystems

Gerresheimer has been a long-standing customer of ours. Since 2001, we have supplied the Bünde location with several customized... mehr lesen

Excella Relies on Proven Technology

Excella GmbH & Co. KG, a renowned pharmaceutical company, relies on the comprehensive solutions from EnviroFALK PharmaWaterSystems for its... mehr lesen

Keine Einträge gefunden

Recirculation Purification – Water Refinement for Electrolysis

All our systems are delivered in a modular design, allowing for custom integration into the overall electrolysis concept.