Easy Maintenance and Service

Anti-Rouging-Concept

Mature Concepts: With Additional Measures for Qualification

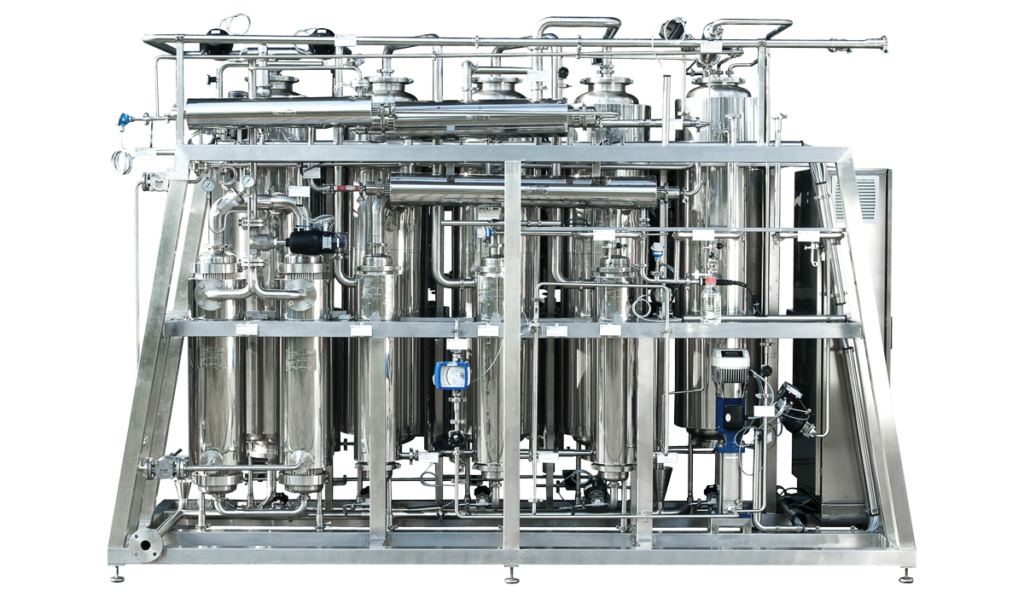

Opt for distillation systems from EnviroFALK PharmaWaterSystems that fully meet your high demands thanks to an energy-efficient system design:

- Twin systems for WFI and pure steam production

- Salinity < 1%

- Full insulation

- Natural circulation process: No contamination buildup

- Optimized operational and maintenance costs

Service

We offer services ranging from the smallest spare part to full-scale plant maintenance. Contact us to learn more about our comprehensive support services!

Trade Fairs & Events

When it comes to solutions for your water treatment, experience genuine enthusiasm in a personal conversation at our trade fairs and events. Get to know us!

References

Many of our customers are leading companies in their industry that have trusted EnviroFALK water treatment systems for years. See for yourself!

Downloads

Customers & Solutions

Pure Media Systems for the New Production Facility of Allergopharma

EnviroFALK PharmaWaterSystems delivers everything. Receive a comprehensive production line that is fully aligned in terms of functionality and quality.When... mehr lesen

Trust That Pays Off - Gerresheimer Relies on EnviroFALK PharmaWaterSystems

Gerresheimer has been a long-standing customer of ours. Since 2001, we have supplied the Bünde location with several customized... mehr lesen

Excella Relies on Proven Technology

Excella GmbH & Co. KG, a renowned pharmaceutical company, relies on the comprehensive solutions from EnviroFALK PharmaWaterSystems for its... mehr lesen