INTELLIGENT TECHNOLOGY FOR

GREATER EFFICIENCY AND FLEXIBILITY

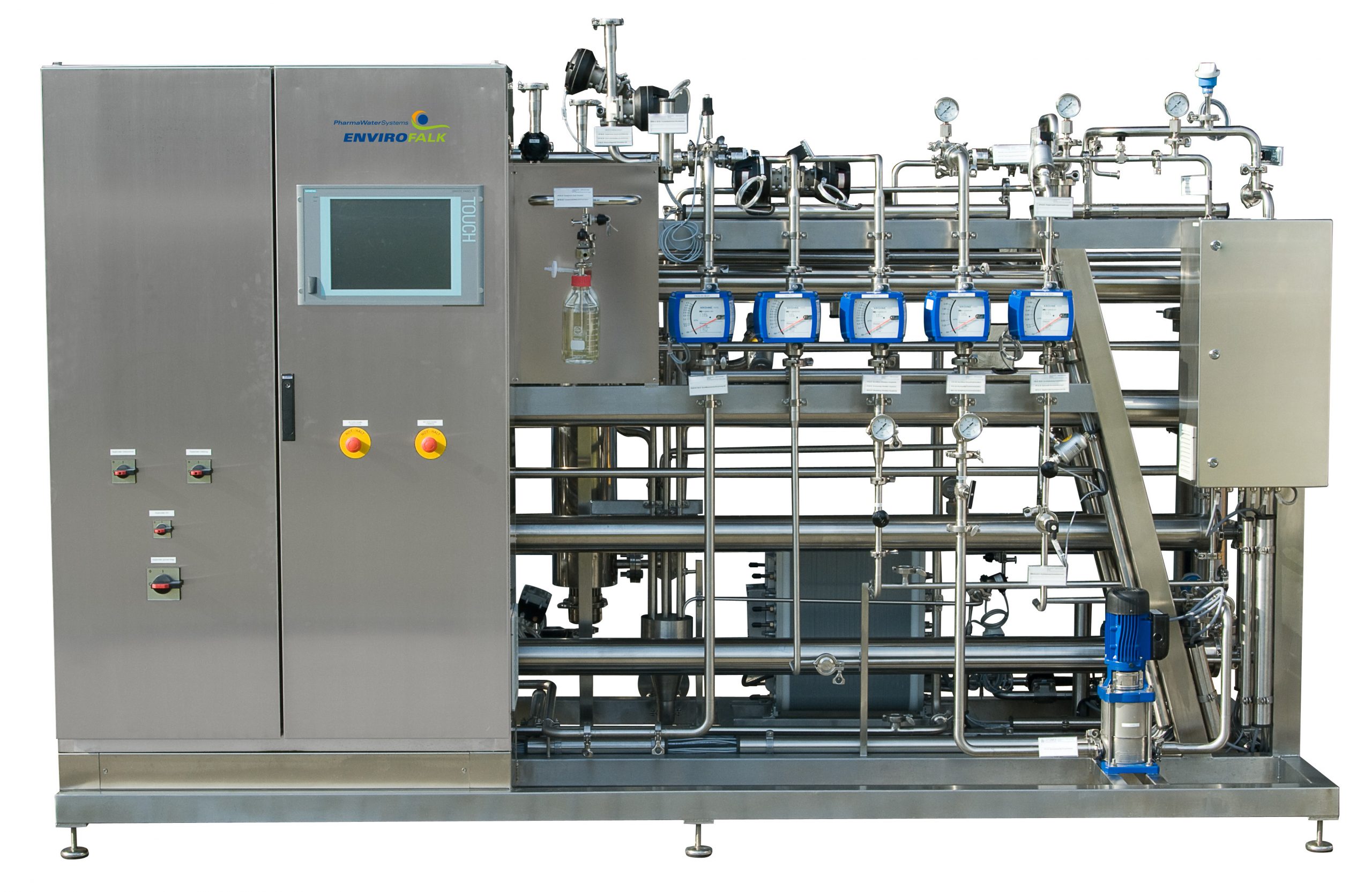

The production of purified water is subject to stringent rules and specifications that must be strictly observed, placing exacting demands on system design. EnviroFALK PharmaWaterSystems supplies PW systems completely made of stainless steel or optionally of PVDF-HP, and places the design focus on maximum microbiological safety and optimised efficiency.

Your system: based on feed water quality, pre-treatment and product requirements

Reverse osmosis units are at the heart of all pharmaceutical water treatment systems – as a physical and robust barrier to ions, organic impurities and micro-organisms. Downstream electrodeionisation (EDI) removes residual ions and ensures that the required conductivity limit is observed. The system is designed with a critical assessment of the local tap water quality and the customer-specific process requirements in mind.

INNOVATIVE TECHNOLOGY

Along with absolute operating and product reliability other technical details play an essential role:

Efficiency/system recovery

Maintenance-friendliness

Individual product specifications

Production flexibility

Operating cost optimisation

A future-oriented plant design, e.g. for subsequent capacity expansions

BRINGING TOGETHER RELIABILITY AND EFFICIENCY MEANS DELIVERING THE BEST OF ENGINEERING – SOMETHING WE KNOW A THING OR TWO ABOUT!

Higher recovery and product

quality, less wastewater

The hydraulic design of the reverse osmosis unit determines the recovery and product quality. Both in RO-EDI and 2-stage RO units, a recovery of ≥ 90 % can be achieved by the addition of a concentrate treatment stage.

Our systems are consumption-controlled: If water demand is low, output is reduced. If the tank is full, the water circulates in the system, ensuring a constant flow through all product water pipes.

EnviroFALK PharmaWaterSystems systems ensure compliance with all regulations and specifications, while keeping operating costs low. We also offer an all-round service programme with 24/7 service, emergency service, inspection, and remote maintenance mode.

Purfified water / reverse osmosis unit

316 L stainless steel, aseptic connections in accordance with DIN 11864

As an alternative: PVDF-HP in BCF welding-technology

Complete hot water sanitisaiton

Concentrate treatment to reduce waste water

Volume-controlled: 10-100%, additional CO2 feed in standby phases

Modular design makes it easy to increase capacity

Water for injection